I started this blog post a good 7 months ago but sadly, lost the whole article before it was published. This time I shall try to be more careful!

The idea for this original pose started out when I was reviewing one of my previous 3D prints called 'Balance' which, as the name suggests, had to be balanced quite carefully or it would topple sideways. The right knee was much too close to the left foot and, as a result, any slight shaking in the room would cause the statue to fall.

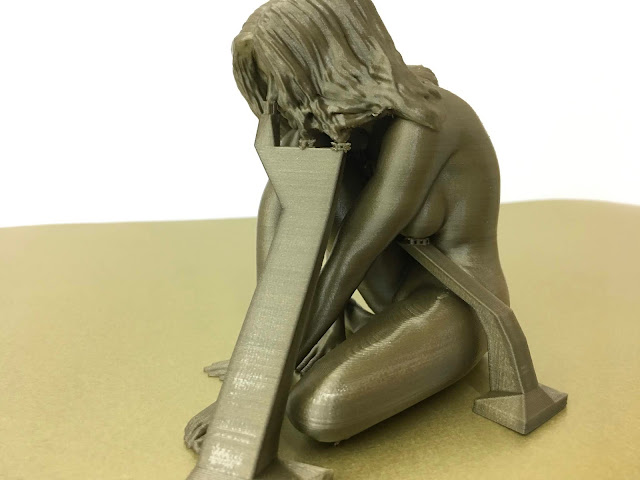

I decided to create a pose where the model would be resting on her right knee and the full length of the left shin, but with a triangular shaped base that would be much more stable. I thought it could work well if the model was reaching down with her right hand, to grasp the right foot, and reaching up with her left hand to touch her hair.

This is the pose that I came up with.

Notice how most of the features are oriented vertically rather than horizontally, which greatly reduces the need for extra support material. In fact, the only place that needed support adding was between the legs to support the genital area.

Tilting the head upwards prevents the chin and tip of the nose from needing any support. The bobbed hair-style is just the right length to rest on the shoulders and clavicles. The left breast is pulled upwards by the raised left arm, but the right breast is also sized so that the underside projects out at 50-60 degrees, which most 3D printers can cope with without needing support.

The hair looks great in these beautiful NVIDIA Iray renders within Daz3D, but there is no way they can be 3D printed without significant modification. My standard process for making 3D-printable models now flows like this:

- Export the OBJ from Daz3D

- Import in Blender - the body and the hair come in as separate objects

- Clean up the body by deleting any unwanted mesh parts like the teeth and front layer of the corneas

- Cut loops out of the inner eyelids and bridge across to the eyeball so that they are cleanly connected

- Completely remodel the hair by shrink-wrapping a fairly dense ico-sphere onto it so that it adopts the general shape of the hair, and then delete the original hair object

- Use Blender's sculpt tools to improve the look of the hair by smoothing out spiky areas first and then adding details to make it look more realistic

- Use a Boolean modifier to combine the new hair object and the body object into a single model

- Export from Blender as an STL file

- Perform any additional mesh clean-up as necessary using netFabb Basic, Windows 3D Builder (and, of course, the wonderful Project Miller if you can find a copy)