I've been wanting to sculpt this pose for a long time. I love the intertwined limbs and the opportunity to rest the chin on the knee to avoid using support material. I think the photo is by Tam Nguyen but I haven’t been able to locate it online.

This type of pose is sometimes called an ‘implied nude’ because the breasts and genitals are not visible in the photo. This doesn’t usually affect the 3D version, of course, since a sculpture can be viewed from any angle, but in this case the only way to pose the figure is with the breasts compressed by the limbs.

My first attempt worked out OK as a pose, but failed as a 3D print because I tried to make the hair out of individual strands and the retractions just ground up the filament - should have guessed!

So I reverted to my tried and trusted formula of selecting a nice hairstyle and then shrink-wrapping and resculpting it in Blender.

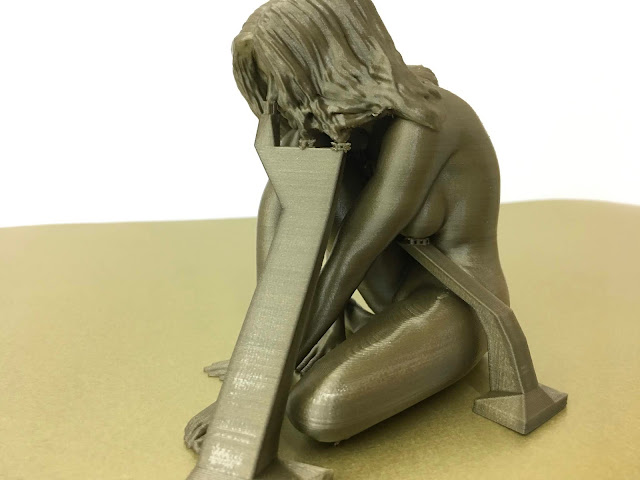

I chose a nice metallic grey Fillamentum PLA filament for this print and sliced the model with Simplify3D. The print was made on my new Sapphire-S coreXY printer from twotrees adapted with a Flex3Drive extruder system. This keeps the print-head as lightweight as possible, giving some of the smoothest prints I've ever achieved.

I'm particularly pleased with how well the sculpted hair has printed on this model. It can still be improved further, though, and I'm working on that. The second version, lower down this page, has more detail sculpted in the flatter areas.

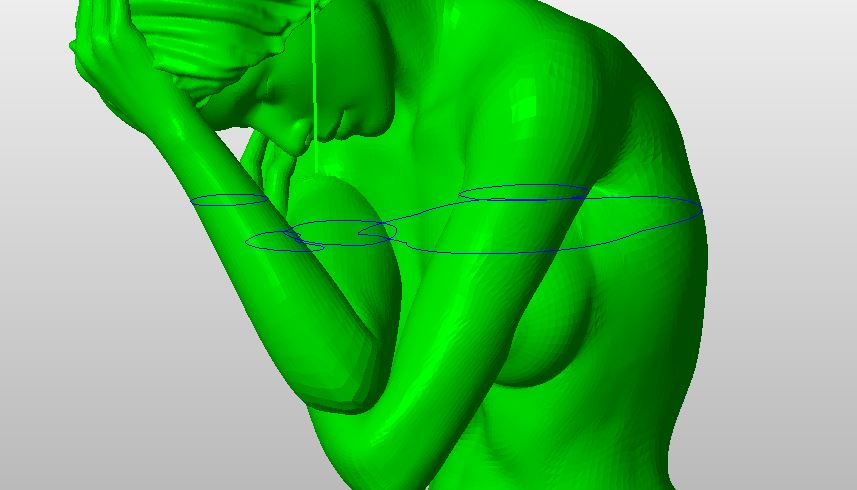

It occurred to me that one way to avoid the ugly scars left after removing support material would be to try and construct a sort of platform sitting over the left leg on which the support could then rest. I fired up Blender and came up with these pieces of scaffolding.

The larger piece supports the nose and the dangling strands of hair. The smaller piece supports the underside of the left breast.

The innovation here is that I realised I could combine manually created scaffolding that projects into difficult to reach areas, with auto-generated support provided by the slicer to fill in the last few millimetres.

By using this approach, I can scale the model up to any size without having to worry about the support gap - it will always be perfect for my printer because the final gap is still decided by the slicer software.

Both support pieces broke away cleanly from the model leaving no scarring anywhere on the thigh or abdomen - a much cleaner result!

Notice in the picture below how the small chunks of auto-generated support sit on top of the large manually created blocks.