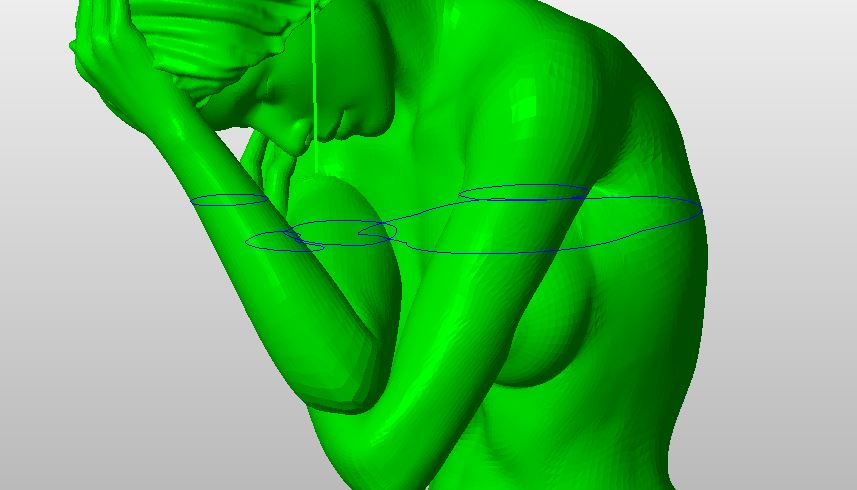

As promised, I took my inspiration from an intriguing pose posted on Rebecca Tun's blog.

Plenty of challenges here for getting the pose right and then printing a decent model. I used the Daz 3D Genesis 3 base model and a pretty long hair style to try and match the photo.

I used my standard techniques for shrink-wrapping the hair in Blender to make a watertight solid model and then, combining the meshes in Project Miller (still one of the best tools for this job, in my view).

Over the last year I have been upgrading my printer to have dual extrusion capability and just recently I have successfully configured the two extruders to work fully independently of each other.

I used Rapunzel Silver PLA from Fillamentum in one extruder, and PolySupport from Polymaker in the other. This combination provides great support with no gaps but then breaks cleanly away once the model is cool. This results in some of the highest quality I have ever achieved. See for yourself!