This photo of Brenda Lynn Acevedo, found on the Bella Donna blog, caught my eye for a couple reasons. Firstly, having her arms (and, in my imagination her legs) held either flat or vertically makes them easy to print without support; and then of course there is the way that her breasts gently rest on the floor giving them a profile that reminds me of a Piet Hein superegg (go and look it up and you'll see what I mean).

The fluid nature of (natural) breast tissue means that it naturally reshapes itself in response to gravity. (Of course, the same is true of all fatty tissue, but the models in these photos don't usually have much surplus fat in other places, so this issue generally only affects the breasts.) Character modelling software allows you to position the limbs, trunk and head in anatomically plausible positions, but also allows you to change the shape, size and position of the breasts. One thing that it doesn't do very well though is to model the impact of gravity on mobile breast tissue; there are add-on pieces of morphing software that give an additional level of control, but nothing I have found yet that mimics the effect of gravity on natural breasts in a reclining position.

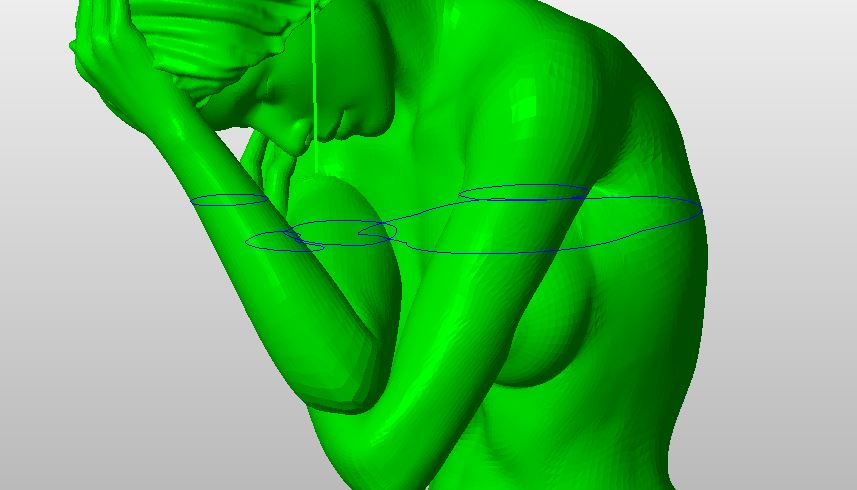

So, after exporting the best pose I could manage from the posing software, I started sculpting in Blender until the breasts had a shape I was happier with and which I was ready to try printing.

Feeling lazy, I used the clock rewind trick to bring Project Miller back to life again and quickly generated a single watertight mesh from the multi-object base and then did one more smoothing iteration.

I used Simplify3D for the slicing and made sure there was plenty of support material around the right arm so that the small point of elbow contact with the bed wasn't put at risk of failure.

I decided to use a nice wood-coloured PLA from 3D Filaprint and after a long 16 hour print this is what the printer produced.

Opinion: I'm generally very pleased with this one. There are couple of areas that could be improved - some distortion around the heel, and rather too little support material in the small of the back and between the shoulder blades.

Postscript: I decided to adjust the layer positions and try a reprint. This one came out even better.